Precision Customization, We Deliver What We Promise

Just share your drawings and specifications with us — we’ll bring them to life with precision. Every universal joint is produced exactly to your requirements, ensuring stable performance and dependable quality.

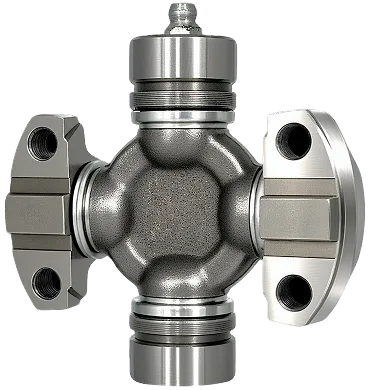

Tough and Durable, Built to Last

We use high-grade alloy steel as the base material, with core cross shafts treated through advanced carburizing processes. This gives our products exceptional wear resistance, fatigue strength, and long service life — ready to perform under even the harshest conditions.

Fast Delivery, No Delays

With an efficient supply chain and optimized production management, we respond quickly to every order, ensuring on-time delivery and helping you stay ahead in the market.

Flexible Cooperation, Supporting Innovation

Whether you’re in the prototyping stage or require large-scale production, we adapt to your needs seamlessly. We’re also eager to support custom product development and performance upgrades based on your existing designs.

Competitive Pricing, Greater Value in Volume

Through large-scale production and continuous process optimization, we maintain top quality while keeping costs low — offering highly competitive prices, especially for bulk orders that deliver the best value for your business.